Liquid-in-metal thermometers use the pressure rise of a liquid that comes along with an increase in temperature, if the volume is kept constant!

In liquid-in-metal thermometers (also referred to as liquid filled thermometers), a liquid is used as a thermometric substance in the same way as in liquid-in-glass thermometers. However, it is not the thermal expansion of the liquid that is measured, but rather the increase in pressure that goes hand in hand with an increase in temperature when the liquid completely occupies a closed volume. In contrast to liquid-in-glass thermometers, the volume of the thermometric liquid therefore remains constant.

The higher the temperature of the liquid, the stronger it tries to expand and the stronger the pressure increase will be at a constant volume. This principle can therefore be used to determine the temperature from the pressure rise on a calibrated scale.

Liquid-in-metal thermometers (liquid filled thermometers) use the pressure rise of a liquid that comes along with an increase in temperature, if the volume is kept constant!

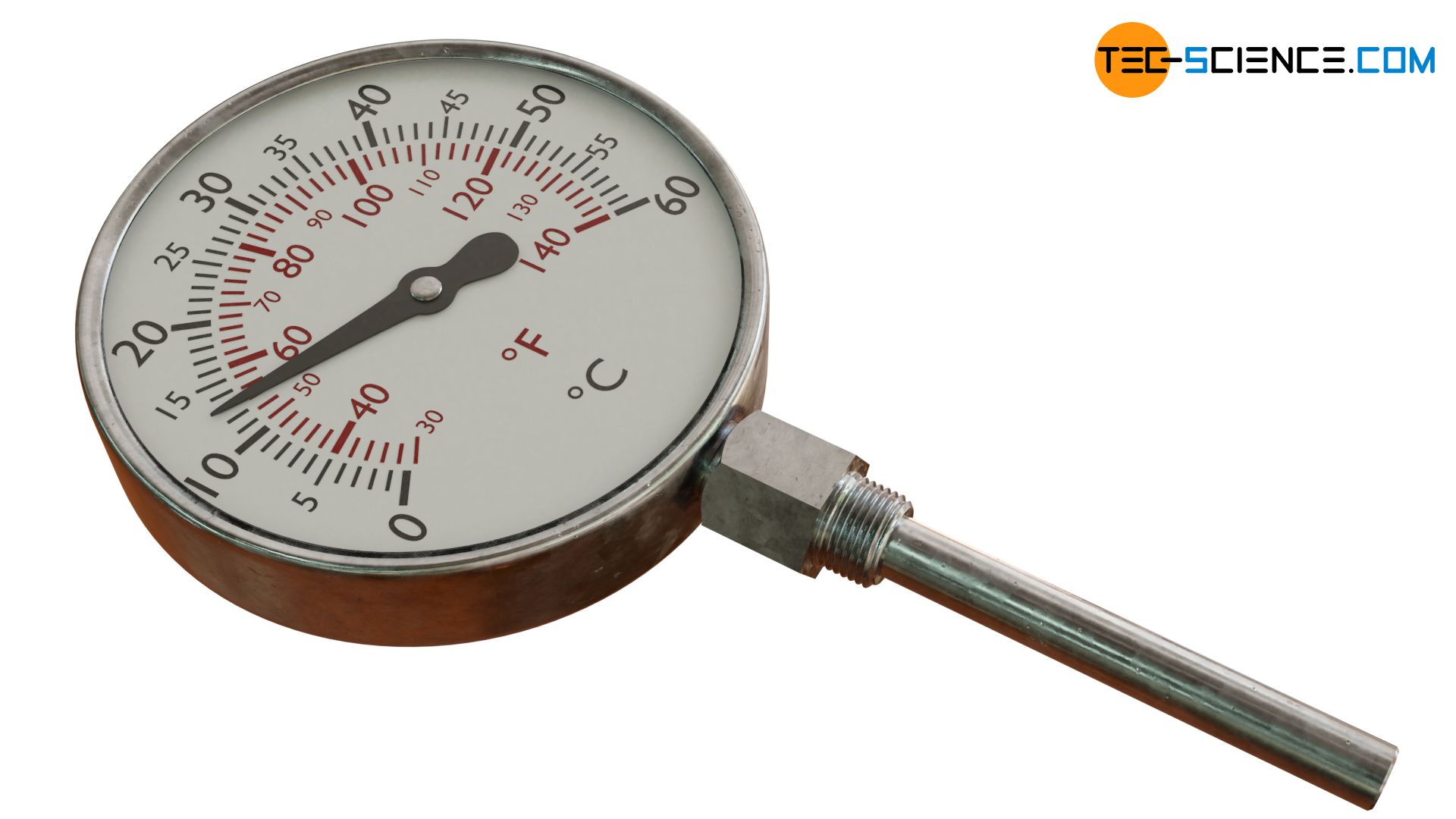

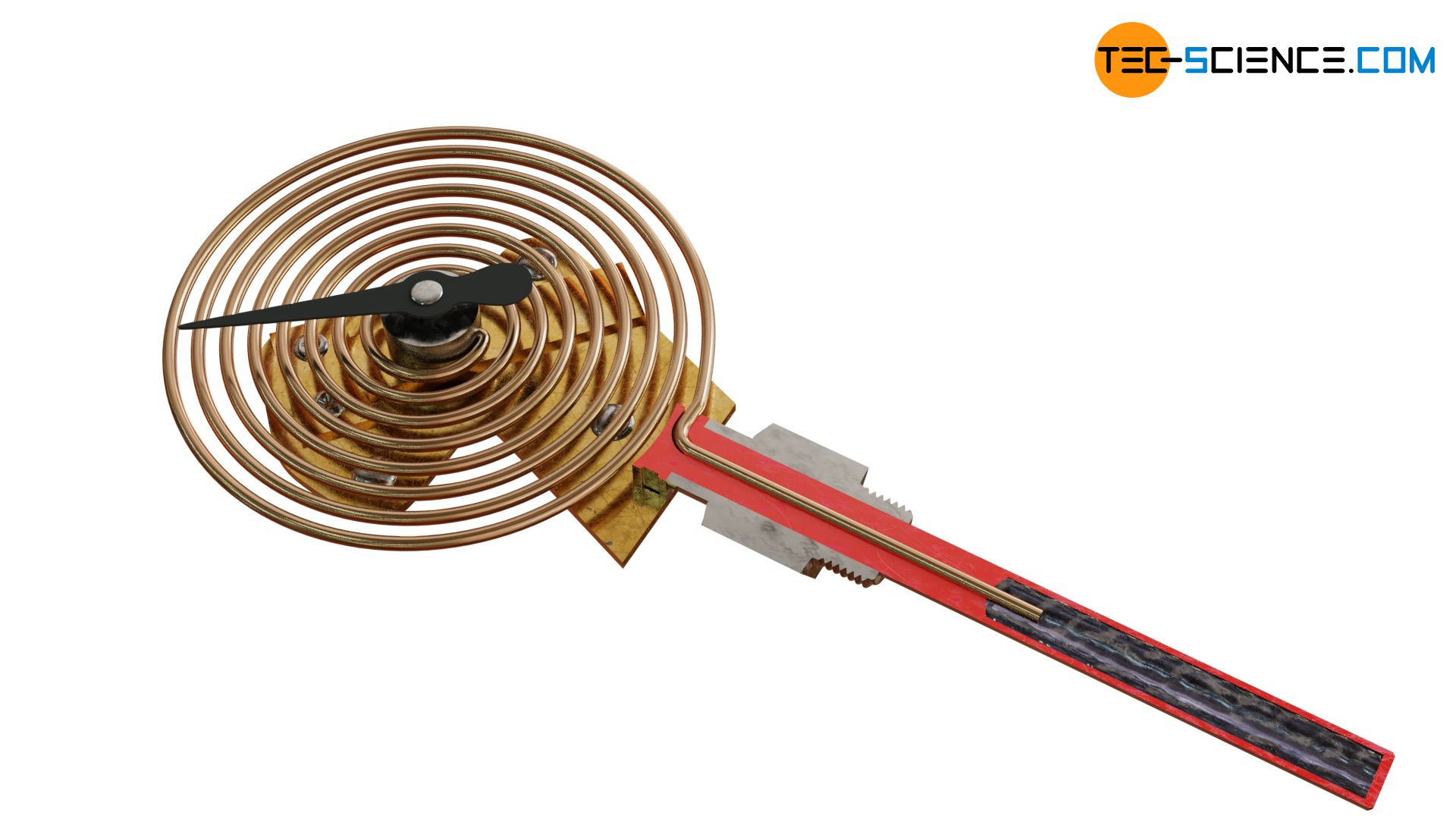

For liquid-in-metal thermometers, the pressure must therefore be measured and converted into a temperature value by means of an calibrated scale. For this purpose, for example, a tube is wrapped into a coil and filled with a thermometric liquid and then sealed on both sides.

If the temperature of the liquid rises and with it the pressure, it tries to bend up the spiral tube like a spring. Such a tube is also referred to as a Bourdon tube. The elastic deformation of the tube at a temperature increase is directly applied to a rotatably mounted pointer. The corresponding temperature can then be read off from a calibrated scale.

So that the temperature display (gauge) and temperature sensor (measuring tube) can be spatially separated, the Bourdon tube has only a relatively small inner diameter and thus contains only a small volume of liquid. The largest volume of liquid is in the sensor tube itself (bulb), which is exposed to the temperature to be measured. Thus the thermometer reacts mainly to the temperature change in the sensor and not to temperature changes in the housing.

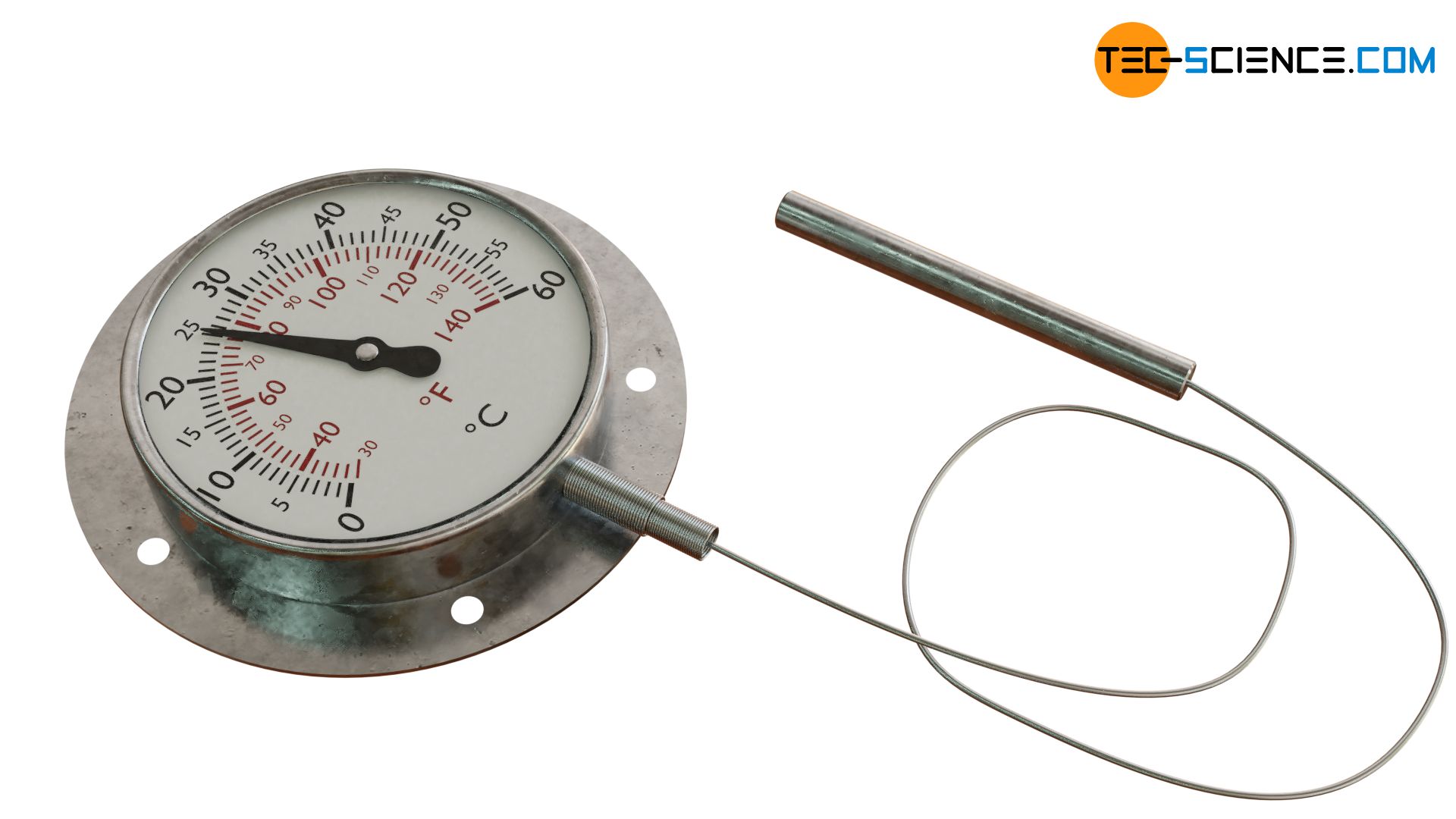

If large distances have to be covered, liquid-in-metal thermometers can also be equipped with a flexible capillary tube that is placed between the Bourdon tube (gauge) and the temperature sensor (bulb). If very large heights are to be covered with a capillary tube, however, a pressure gradient due to the hydrostatic pressure may have to be considered, which falsifies the measurement result.

Liquid filled thermometers can also be equipped with switch contacts that trigger an electrical signal when a certain temperature is exceeded or undershot. Such thermometers can then be used in control engineering.

However, it must be noted that liquid-in-metal thermometers react relatively slow to temperature changes. This is due to the relatively large heat capacity of the thermometric liquid, as liquids generally require a relatively long time to adapt to the temperature changes. At this point, gases would react much faster to temperature changes than liquids. For this reason, gas-in-metal thermometers (gas filled thermometers) have been developed, which will be discussed in more detail in the next article.