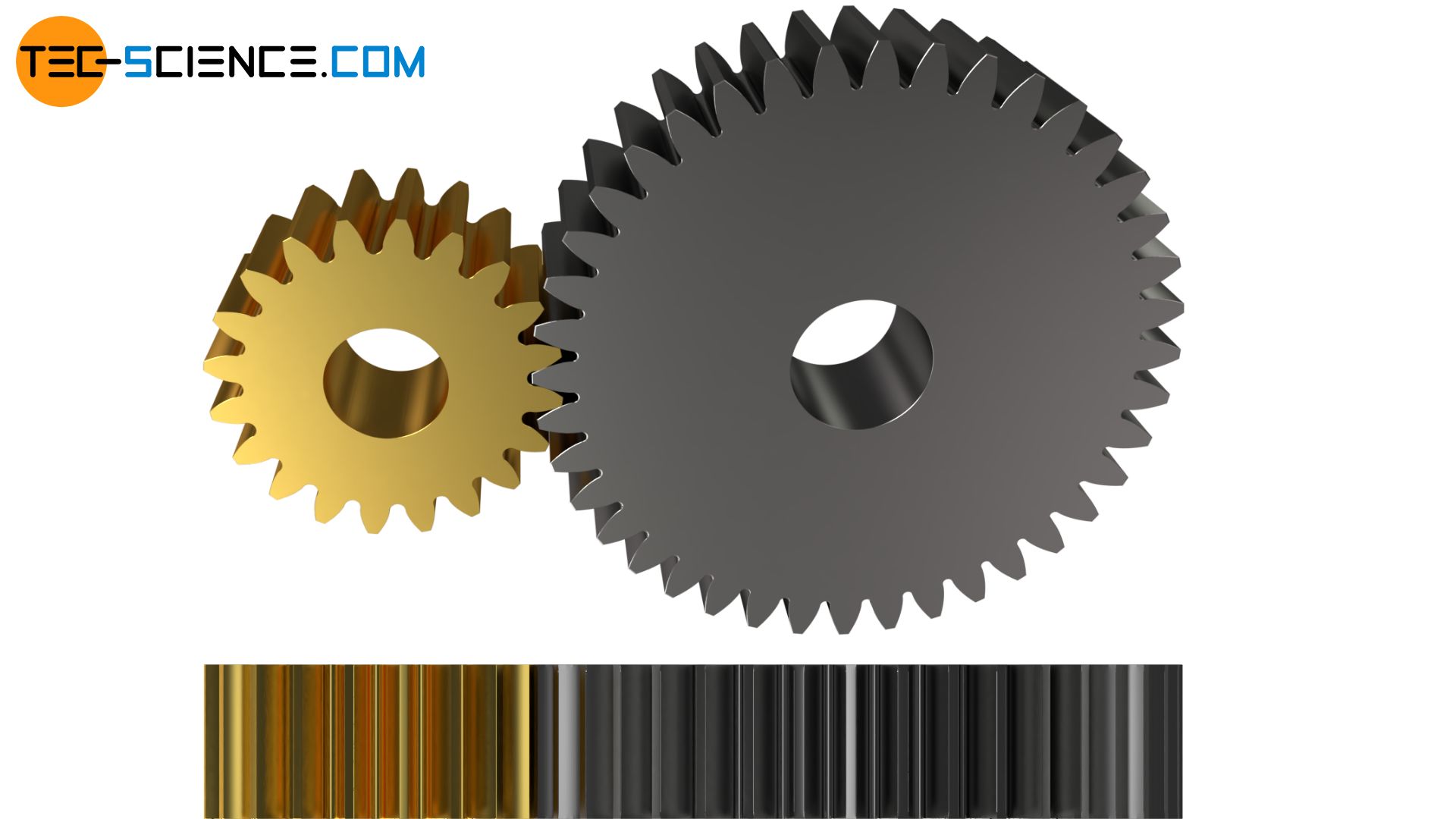

Straight-cut gears (spur gears) are the simplest type of toothing. In a spur gear, up to 3 teeth are in mesh at the same time.

If the teeth of a toothed gearwheel run in a straight line, i.e. in the direction of the rotation axis, it is referred to as a spur gear or a straight-cut gear. Such a toothing can be produced very cost-efficiently by gear hobbing, gear planing or gear shaping.

With spur gears, up to three teeth mesh simultaneously with each other. However, at least one tooth must always engage the mating gear to ensure continuous power transmission. The more teeth are engaged at the same time, the lower the load for each tooth and the higher the power that can be transmitted.

Since with spur gears the entire width of a tooth engages at the beginning of meshing, the force transmission also suddenly starts and abruptly breaks off at the end of meshing. This leads to relatively high noise levels. Spur gears are therefore only suitable for low circumferential speeds.

Spur gears are the simplest and therefore most cost-effective type cylindrical gears! Spur gears do not allow the transmission of excessive torques and speeds.

Higher rotational speeds and torques can be achieved with the helical toothing described below.