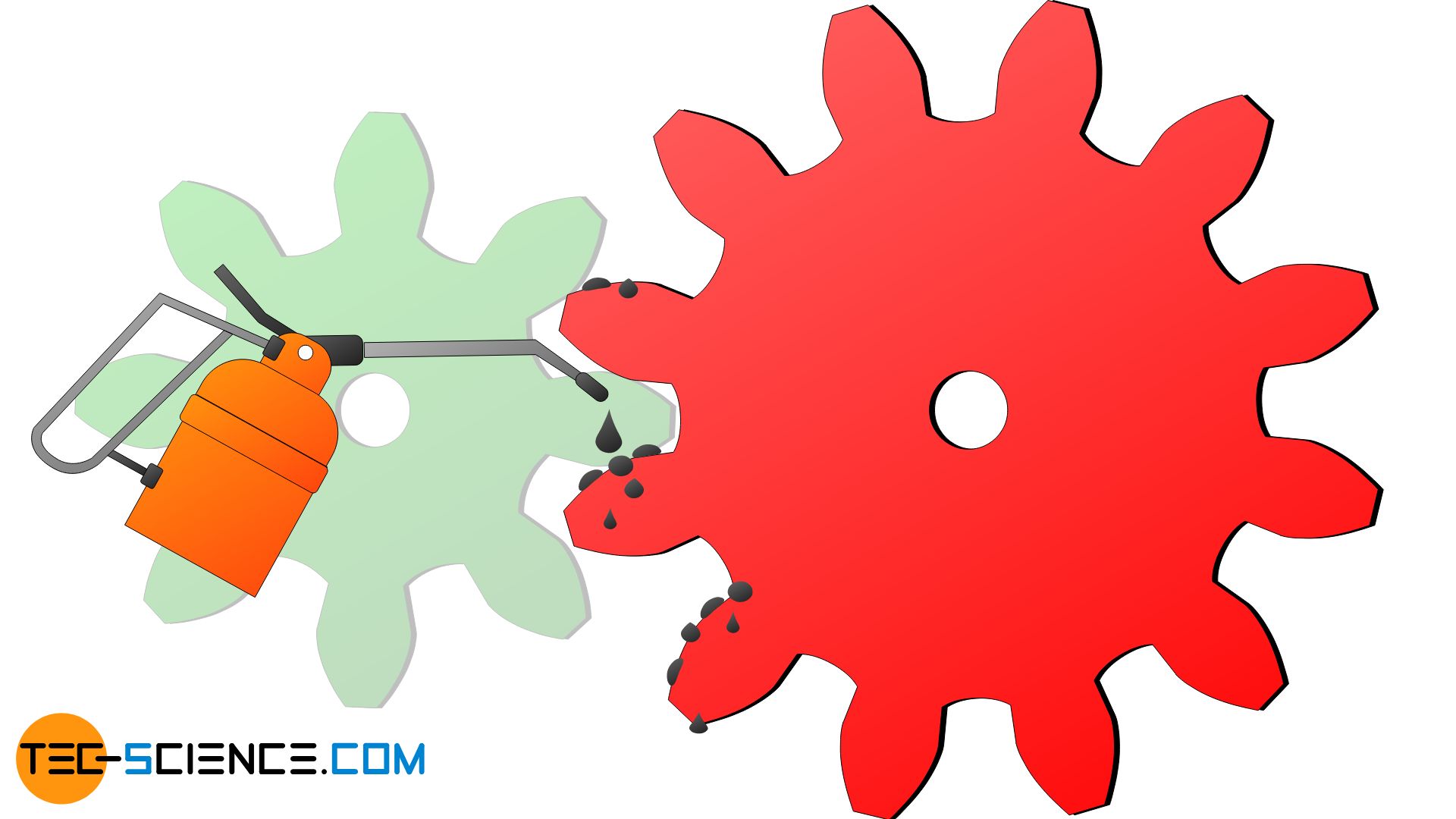

Gears must be lubricated due to the high stress (friction) when meshing with another gear.

Introduction

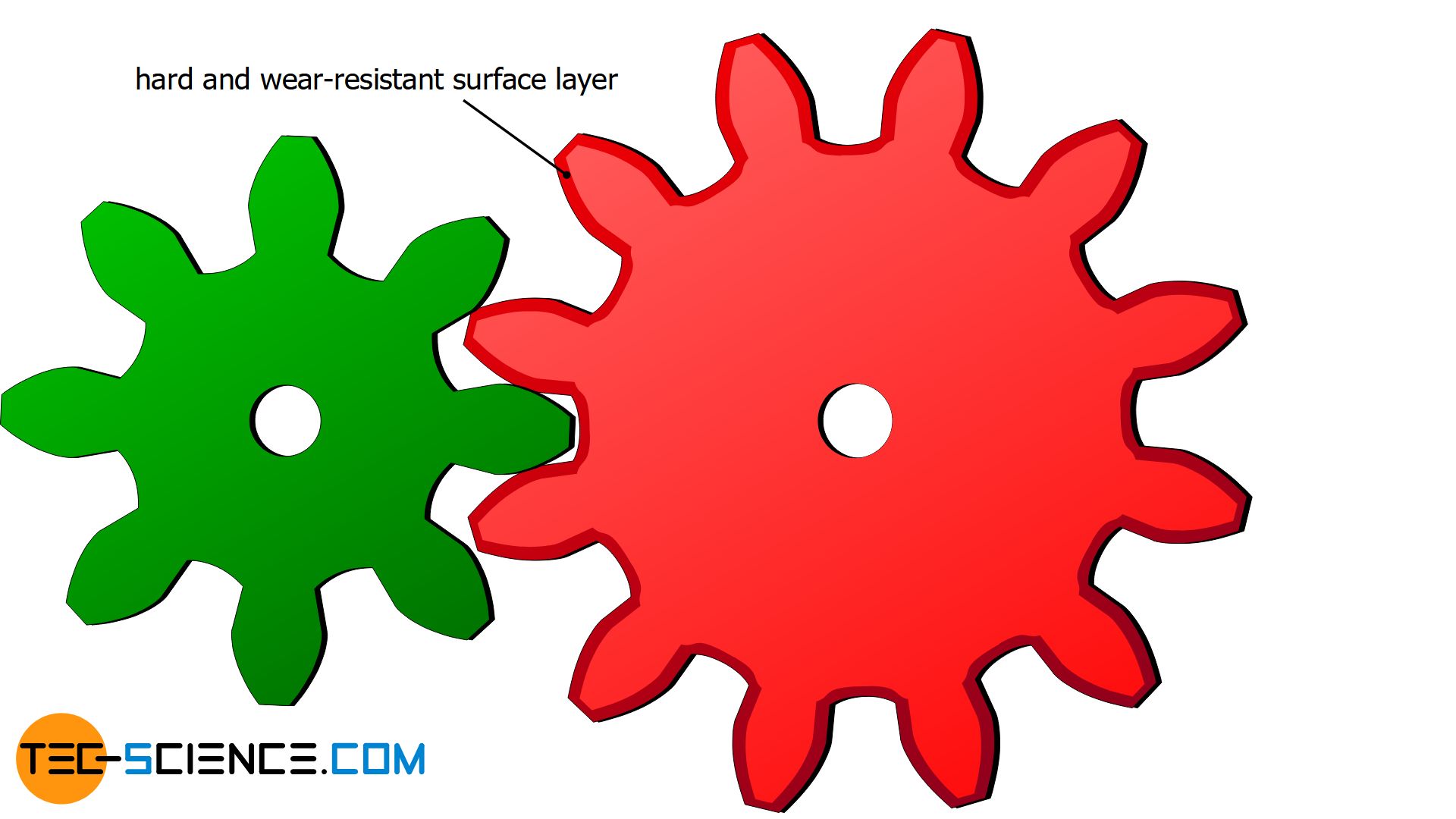

Gear wheels of transmissions are subject to wear due to sliding processes on the flanks. Therefore, the teeth must generally have a hard and therefore wear-resistant surface. For this purpose, the surface may have to be specifically treated. With steel gears, a hard and wear-resistant tooth flank can be achieved by surface hardening (case hardening) by means of induction hardening.

Another way to reduce wear is to evaporate special layers onto the surface of the gear. For example, certain steels (nitriding steels) can form a hard and wear-resistant nitride layer on the surface by a heat treatment with nitrogen (called nitriding). For example, worms for worm drives are often made of nitriding steel.

However, such heat treatments are not suitable for every gear material (e.g. plastic gears) or make economic sense or they alone are not sufficient to reduce wear to the desired level. In general, gear drives must therefore be additionally lubricated to keep wear on the teeth as low as possible. The measures presented below to reduce wear are becoming more and more effective from case to case.,

Types of lubricants

Non-liquid lubricants such as graphite are used for so-called dry lubrication. Such dry lubricants reduce wear generally more effective than merely heat treating the surface.

In dry lubrication, the force-transmitting elements touch each other via friction-reducing solids!

Compared to dry lubrication, the use of liquid lubricants (lubricating oils) or paste-like lubricants (greases) can significantly reduce wear on the tooth flanks (liquid lubrication).

In liquid lubrication, the force-transmitting elements touch each other via a friction-reducing liquid film!

If the liquid film does not allow any direct contact between the components, pure liquid friction is present. The prerequisite for this is that the lubricant is under high pressure in order to be able to apply the necessary forces to keep the components apart from direct contact. Wear for pure fluid friction is virtually zero. In general however, the tooth flanks still have direct contact with each other. This is then referred to as mixed friction between liquid friction and solid friction.

Maintenance

The lubricating oils and greases used in liquid lubrication are generally subject to ageing. Dirt particles or abrasion from the rubbing contact points are introduced into the oils or greases over time. For this reason, lubricating oils and greases must be regularly replaced or refilled. This is also the reason for regular oil changes in cars.

Lubricants are subject to aging and must be checked regularly and replaced if necessary!

Ensuring lubrication

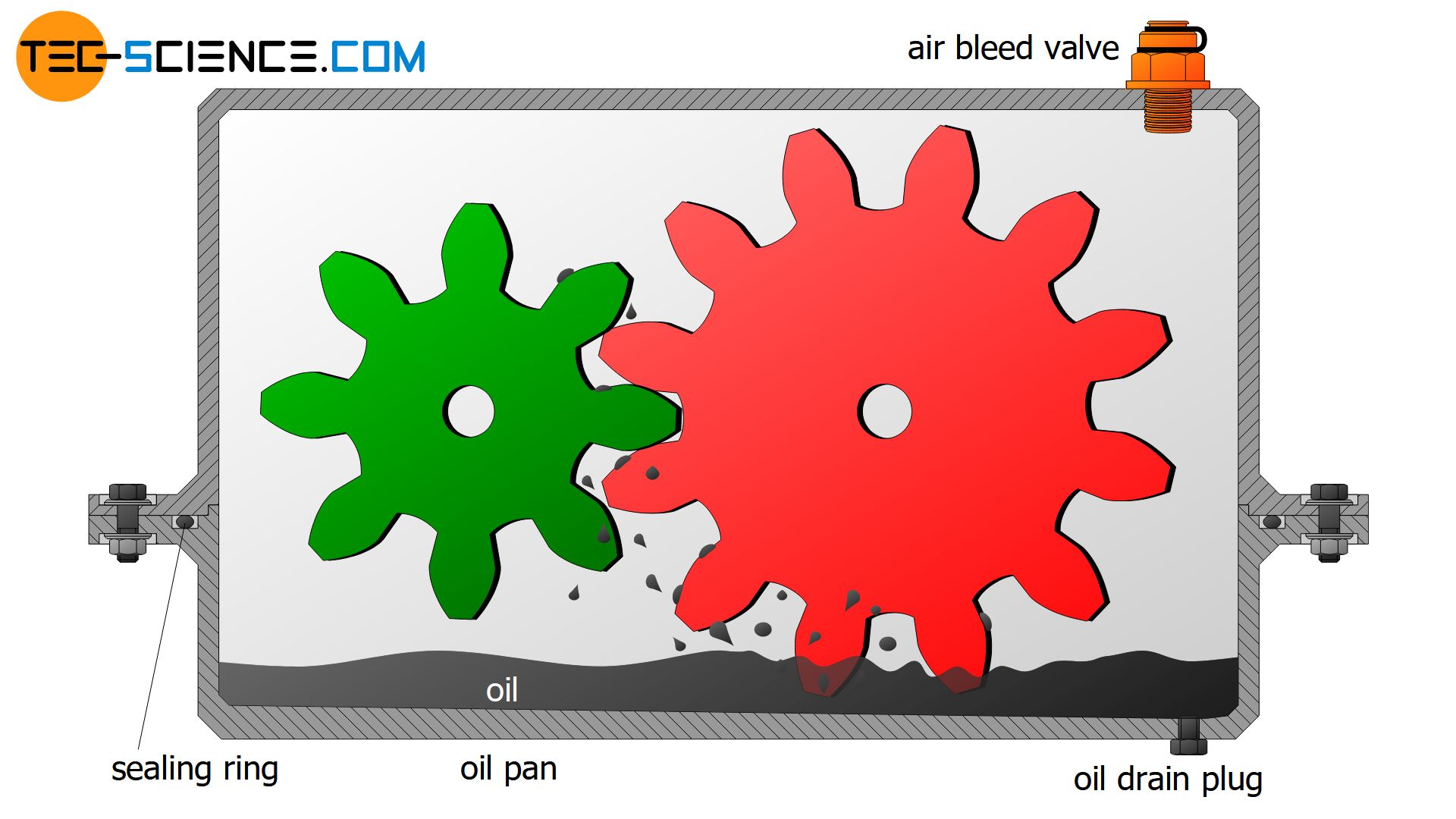

While lubricating greases adhere to the components to be lubricated due to their viscous behaviour, however, the liquid lubricating oils will settle off the gear wheels over time. To ensure permanent lubrication, it is sufficient, for example, if one of the gears is immersed in an oil pan and the lubricating oil is distributed throughout the entire gearbox due to splashing effects. However, the resistance when immersed in the oil pan causes additional efficiency losses.

However, this principle of immersion can only be used in closed gearboxes in which the housing is sealed. For technical equipment which is used in different positions (e.g. a demolition hammer), it must also be ensured that lubrication is guaranteed in every conceivable position and that at least one gear wheel dips into the oil.

In addition, when designing closed gear units, care should be taken to ensure that it is possible to change oil or fill new oil at a later date without having to disassemble the transmission completely. For this reason, such gears often have an oil drain plug that allows an uncomplicated oil change without having to disassemble the gear housing.

It must also be considered that the gearbox heats up during operation. This leads to overpressure in the sealed housing. Excessive pressure may cause the gear oil to be forced out of the housing despite the seals. For this reason, gear units that are exposed to high temperatures are equipped with a air bleed valve that can be used to reduce the overpressure.

To ensure that there is always enough oil in the gearbox, it is often equipped with an oil level indicator. This indicator must be checked at regular intervals and, if necessary, oil refilled. The figure below shows the oil level indicator of a demolition hammer. In this case, the oil gauge also serves as an oil drain plug through which the oil is directly refilled.