Eddy current testing is used to non-destructively inspect components for surface defects such as cracks.

With eddy current testing, electrically conductive materials can be examined for pores, inclusions and cracks in the area near the surface. Layer thickness and microstructure tests are also possible with this method.

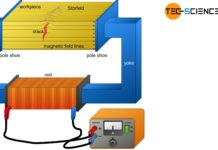

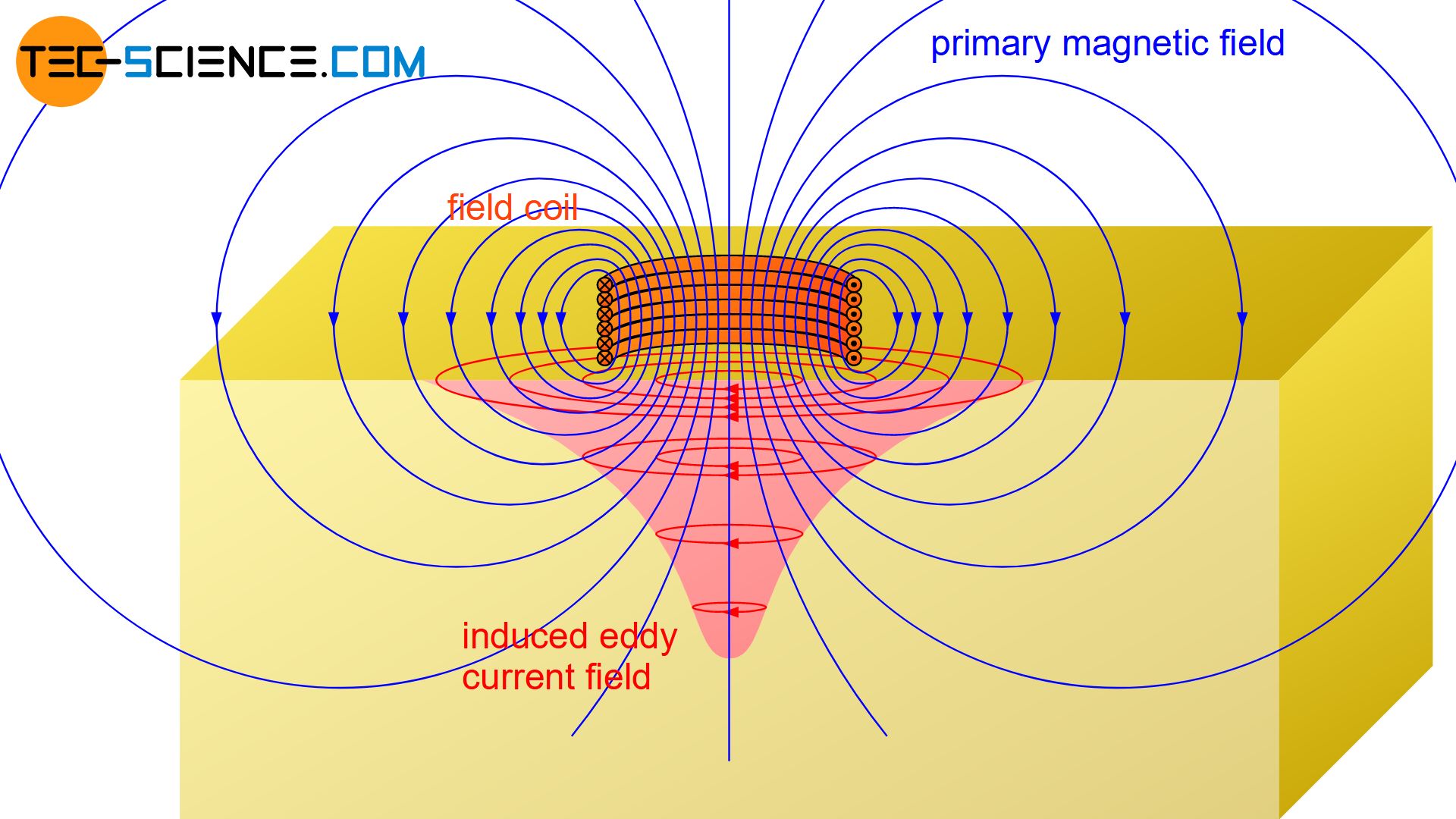

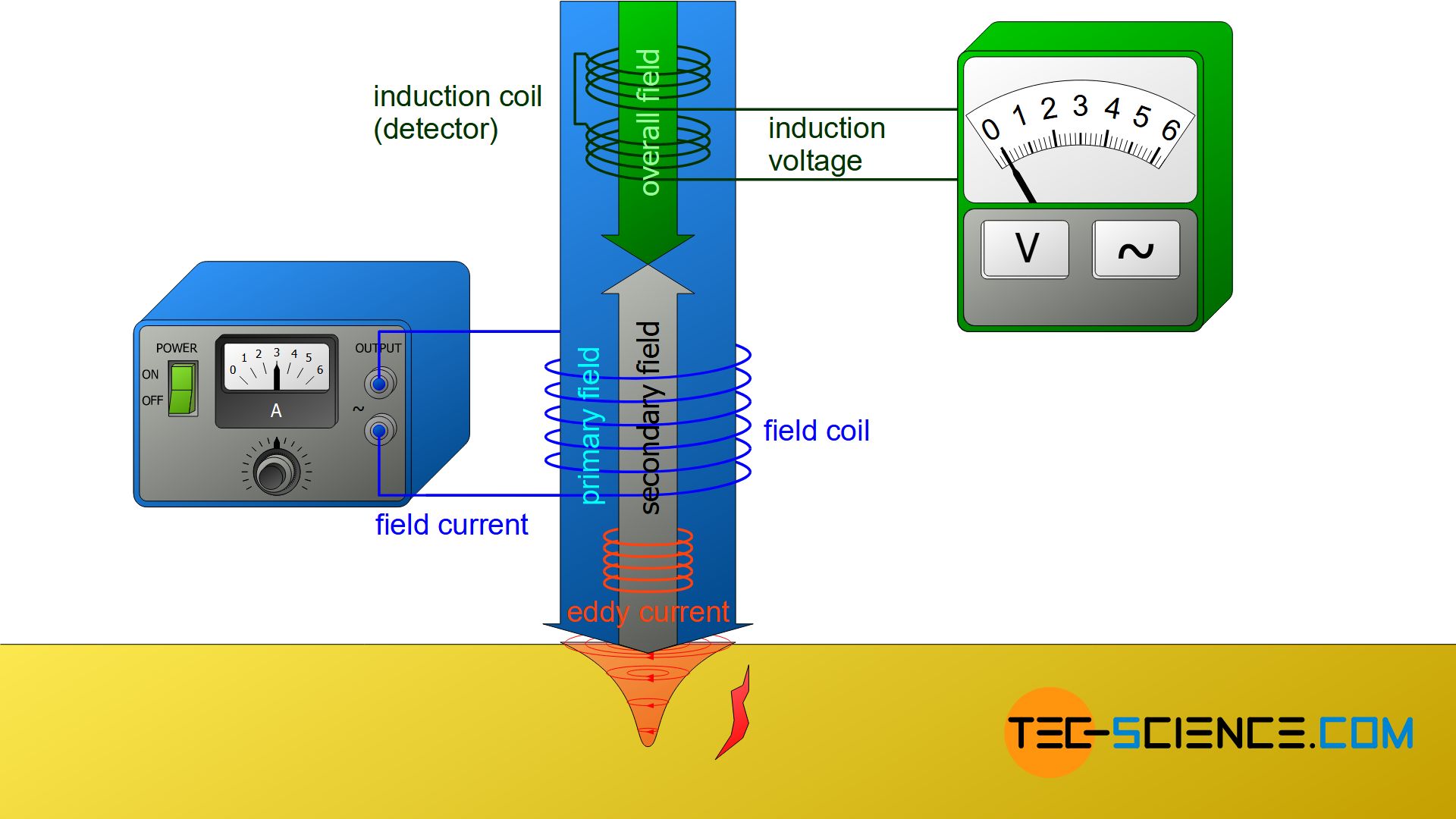

Eddy current testing is based on the principle of electromagnetic induction. For this purpose, a constantly changing magnetic field (primary field) is first generated in an field coil by an alternating current.

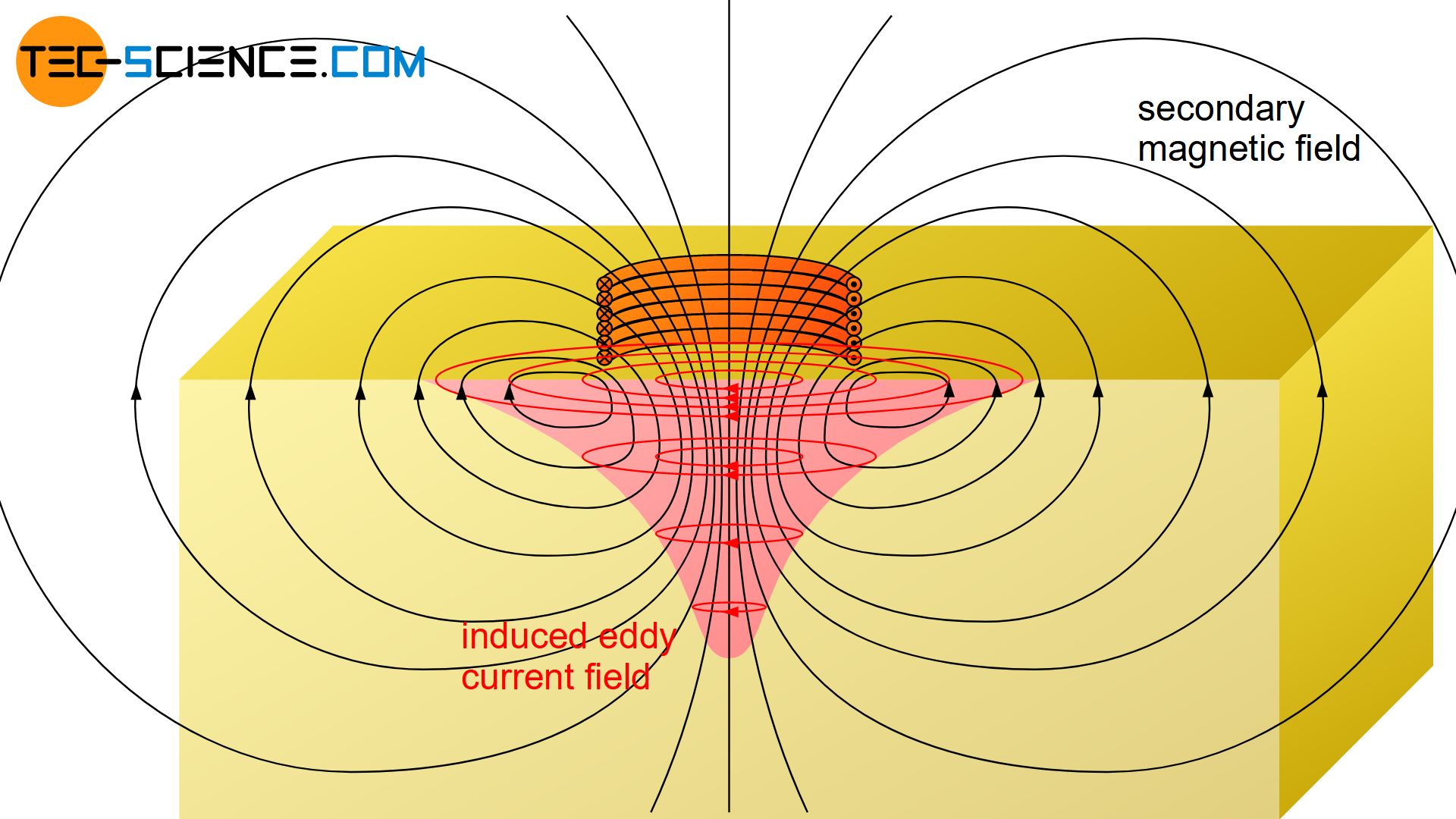

This alternating magnetic field induces an annular current flow near a metallic surface, also known as eddy current. This eddy current also changes constantly in accordance with the alternating primary magnetic field of the field coil. The eddy currents can be regarded analog to the circular currents of the field coil and thus also generate a magnetic field (secondary field).

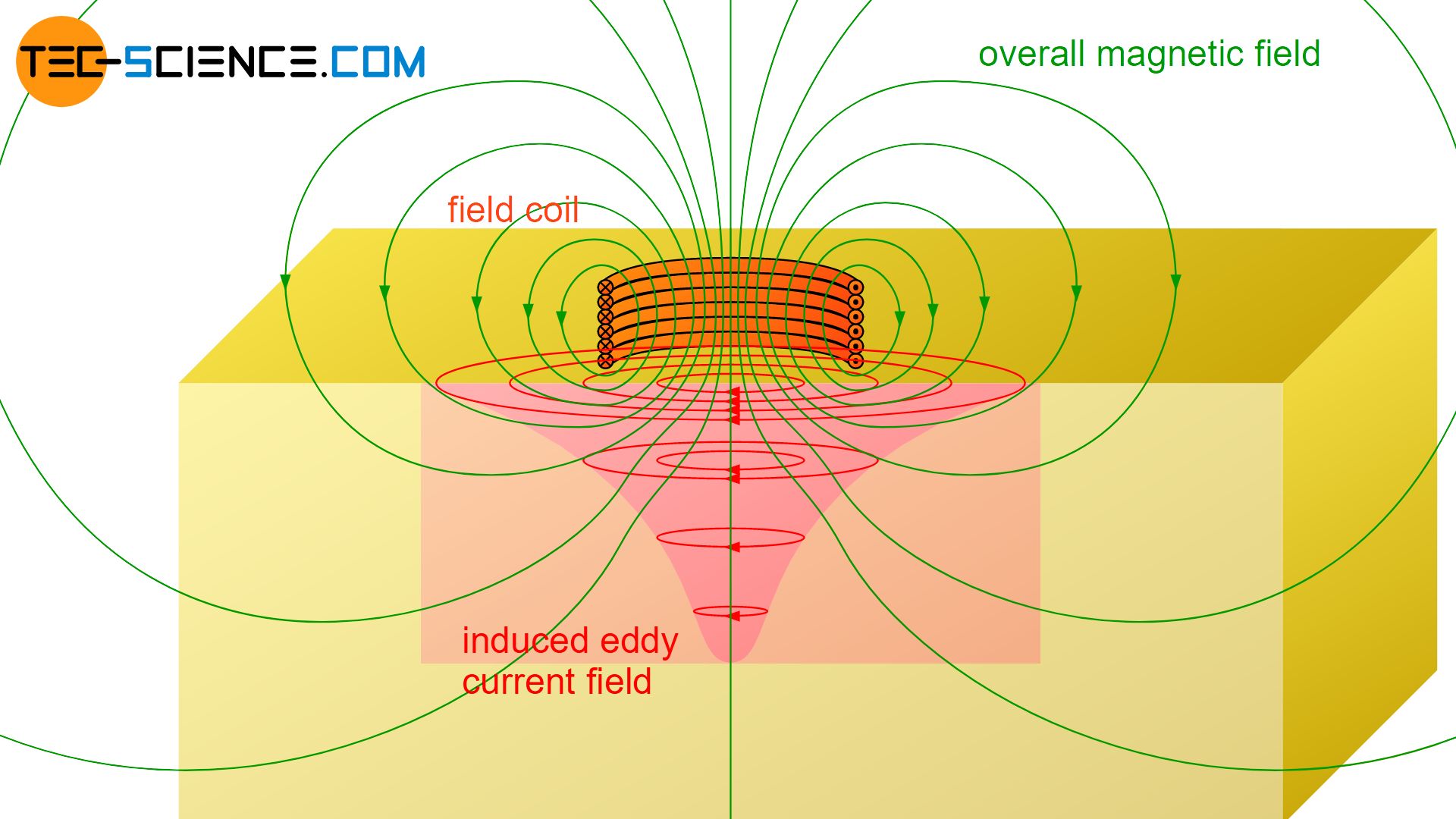

The secondary magnetic field induced in the workpiece by eddy currents is directed in the opposite direction to the external primary magnetic field of the field coil (Lenz’s law). The secondary field thus weakens the primary field and a somewhat weaker overall magnetic field is produced.

Depending on how good or bad the surface to be tested conducts the current, more or less strong eddy currents are formed. This in turn has a direct effect on the strength of the secondary field and thus on the overall field. The magnetic properties of the surface to be tested also influence the secondary field and thus the overall field. At cracks, pores or other inclusions, the electrical and magnetic properties usually change very strongly, so that the total magnetic field changes there. The change of the magnetic field serves as proof of defects.

Note that ultimately only the overall magnetic field actually exists physically. The primary field and the secondary field itself do not exist, since they superpose and only the overall field will be present.

In order to detect the overall field or rather its change, the induction effect is again used. The constantly changing overall field creates an induction voltage in induction coil which is implemented in a detector. This induction voltage in the induction coil ultimately serves as a measurement value, since the induction voltage at the induction coil also changes as the overall magnetic field changes.

The induction coil is integrated directly inside the field coil. To increase the measurement sensitivity, two induction coils can also be connected against each other. In this case, it is not the induction voltage of the induction coil that is measured, but the much more sensitive difference in the two induction coil voltages.