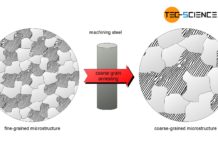

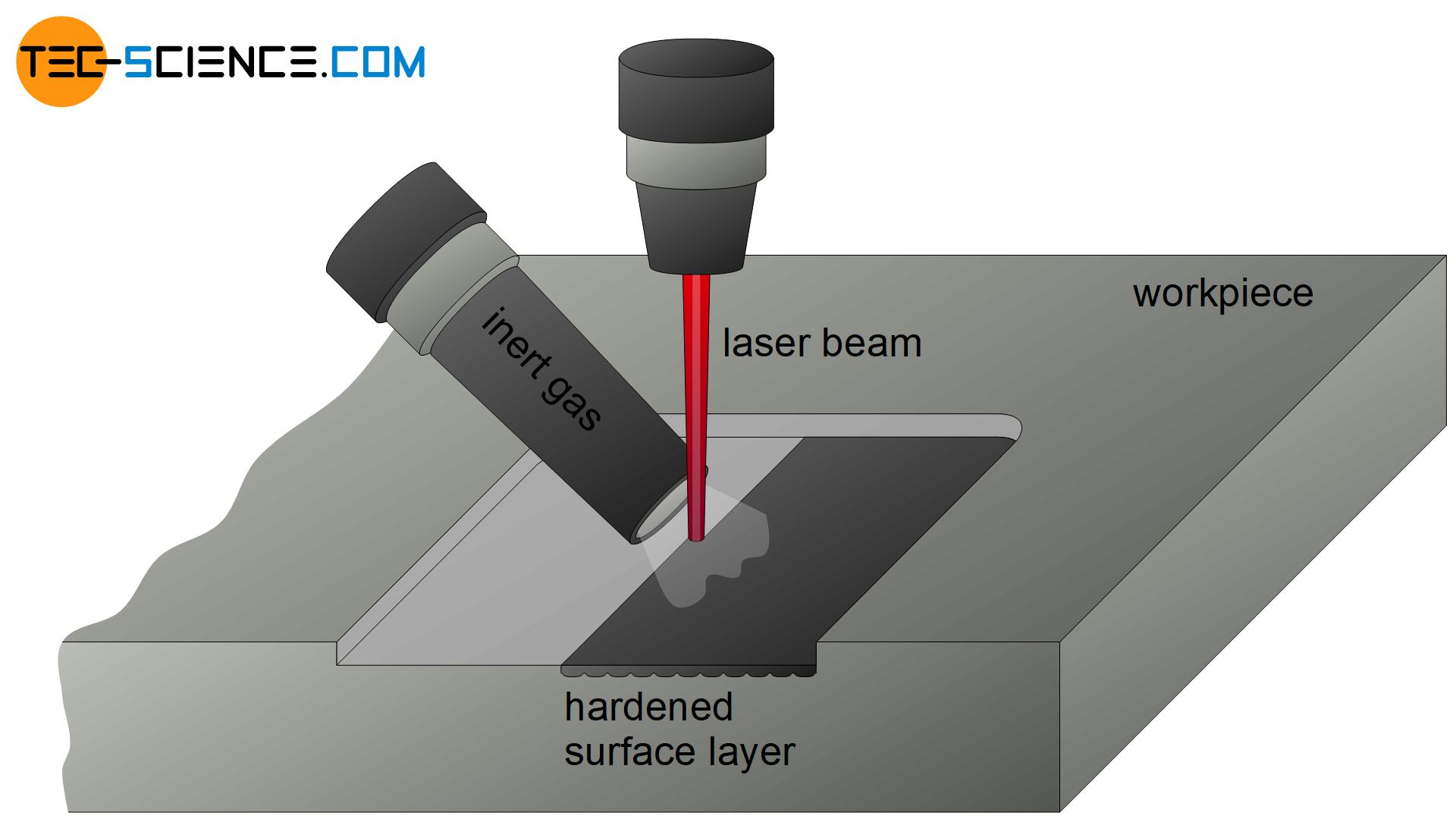

With laser hardening, the surface is heated by a laser beam and quenched by heat dissipation in the workpiece (self quenching)!

Laser-beam hardening (laser hardening) offers even shorter heating times of the surface than in induction hardening. This significantly reduces the already low hardness distortion and scaling. Under inert gas, oxidation of the surface can even be completely prevented.

In laser hardening, a laser beam with a very high specific power (about factor 10 compared to induction hardening) is guided over the workpiece surface to be austenitized. The enormous thermal output of the diode laser of several kilowatts results in a temperature just below the melting point in a very short time! Since the heat input is limited only to the local focal spot of the laser, unnecessary heating of unwanted areas is avoided. This means that the locally heated area is quickly quenched by the cooler surrounding areas. This so-called self-quenching eliminates the need for quenching with water.

With laser hardening, the surface is heated by a laser beam and quenched by heat dissipation in the workpiece (self quenching)!

The laser spot covers a track width of 1 to approx. 50 mm, depending on focusing and process control. Larger surface layers have to be scanned line by line with the laser. Typical hardening depths with laser hardening are in the range of 0.1 mm to 2 mm. As is the case with induction hardening, the smaller the surfaces to be hardened and the shallower the surface layer depths, the greater the cost-effectiveness of laser hardening. Laser hardening is particularly suitable for areas that are very difficult to access, such as tapped holes.

With laser hardening, only small surfaces can be hardened economically. The hardening depth can be kept very low!