The aim of diffusion annealing is to compensate for concentration differences!

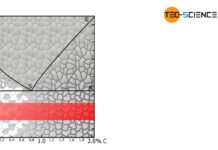

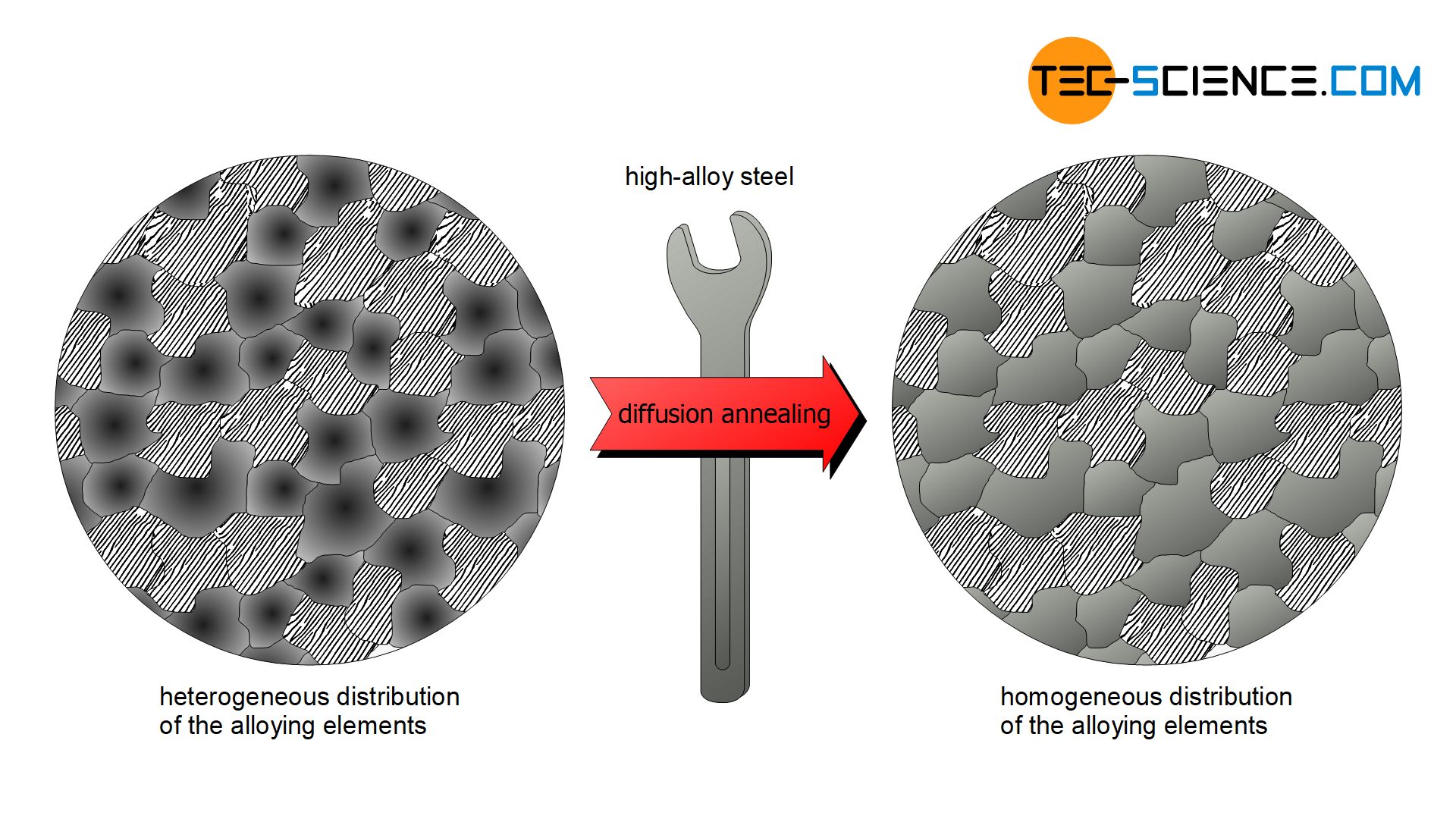

When steels with high alloy concentrations solidify, the alloying elements may not be distributed homogeneously in the microstructure or in the individual crystals. Such concentration differences within the individual crystals are also called microsegregations.

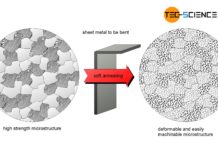

With different alloy concentrations, there are also different properties within a grain which may weaken the microstructure. That is why such microsegregations must always be prevented. However, the formation of such concentration differences cannot always be prevented from the outset due to the finite cooling rates. For this reason, differences in concentration within a microstructure must be eliminated by subsequent heat treatment. This can be done by diffusion annealing.

The aim of diffusion annealing is to compensate for concentration differences!

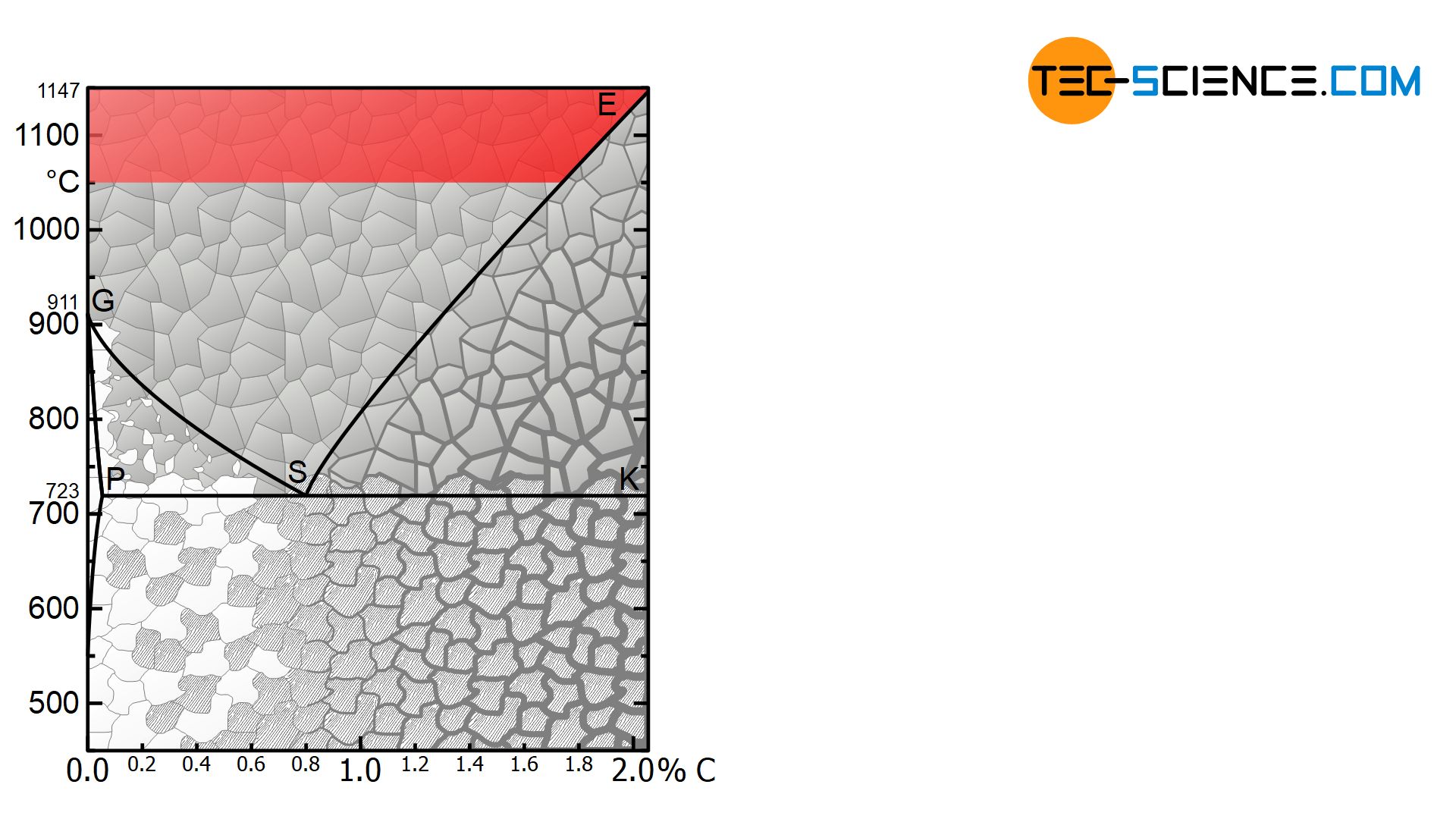

During diffusion annealing, the steel is annealed to relatively high temperatures in the range between 1050 °C and 1300 °C. This ensures that the diffusion processes can take place to a sufficient extent so that the atoms can cover the relatively long diffusion paths. However, this usually requires several hours of annealing time.

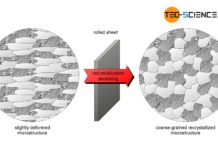

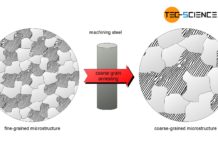

Disadvantage of diffusion annealing is the formation of coarse grains due to the high temperatures. Although this could be reduced by reducing the temperature, longer annealing times would then be necessary and diffusion annealing would no longer be economical. If coarse grain formation cannot be prevented during diffusion annealing, the coarse grain structure must be subsequently removed again. This can be achieved by normalizing.

Since microsegregations occur during the solidification of a steel, they are usually removed directly in the steel mill on the ingot. Especially as the process is very energy-intensive and places high demands due to the high temperatures and long annealing times.